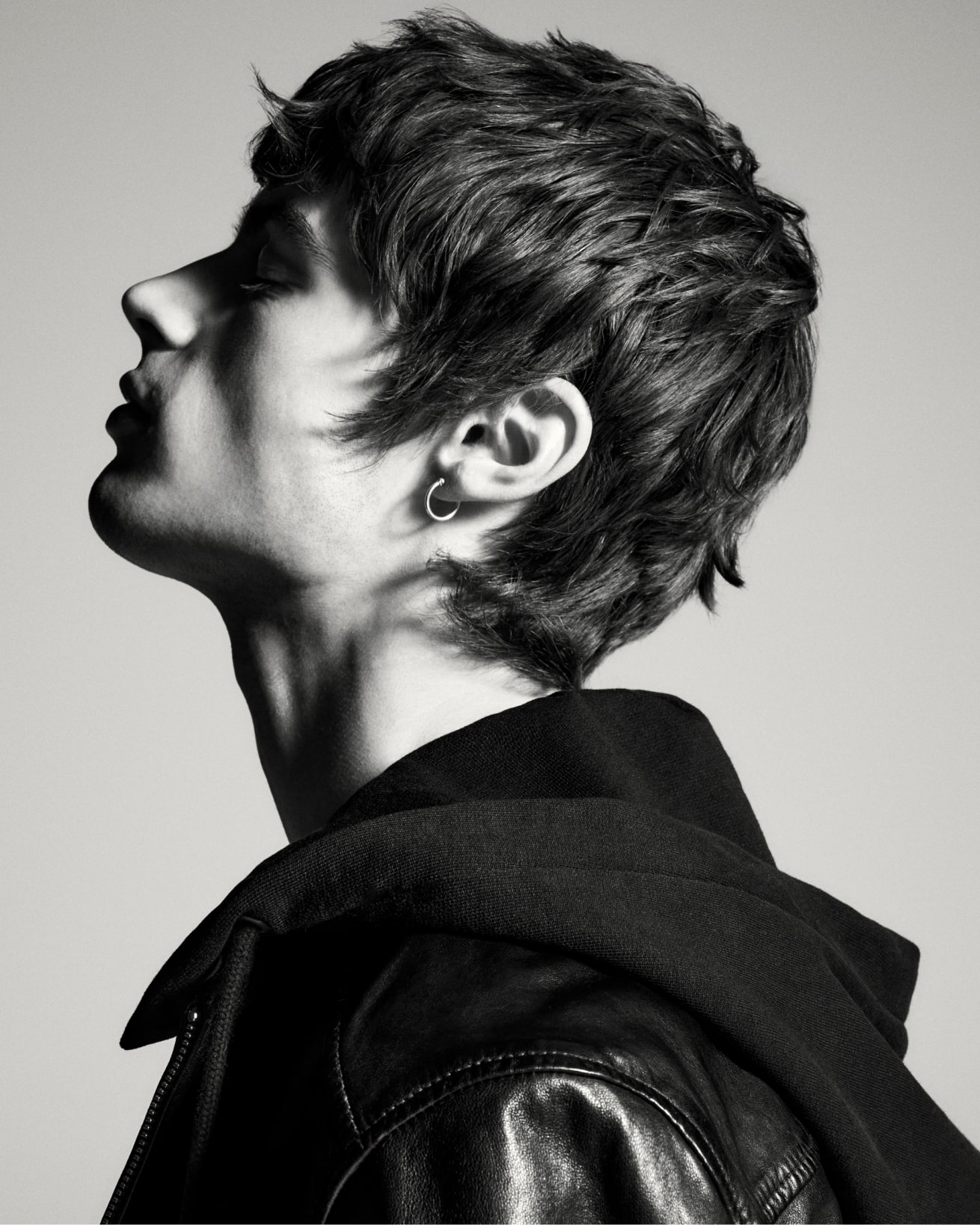

With incremental changes for right now, and larger goals for the future, our sustainability efforts are always growing. We recognise we have a responsibility towards our planet, and the people involved in making our products, so we’ve developed a new uniform collection using recycled yarns, responsible wools, and organic cotton.

“At AllSaints we see it as our

responsibility to not only help our

customers look good, but also

feel good, in the knowledge that

we have carefully considered the

materials used as well as the

processes involved in creating

our collections for them.

Understanding what

something will be made of and

how it will be made are

prerequisites for us before any

design goes into production.”

PETER WOOD, CEO

Looking to start making more responsible fashion choices, but don’t know where to start? Is the industry terminology leaving you confused and overwhelmed? Don’t worry, we’ve broken down our key materials and sustainable certifications into easy bite-sized chunks to make your life a little less complicated…

RESPONSIBLE PRODUCT

A responsible product is any item where at least 50% of the main fabric (i.e. bulk weight of the item) is composed of materials such as organic cotton or recycled materials. This is backed up by certifications which we receive for the products that we make claims against.

We know there is no such thing as a 100% sustainable product, but by producing high-quality collections using the best certified materials, all while looking after the people that make the products, then we know we are doing our best. We continually look at ways to innovate.

THE MATERIALS WE WORK WITH

We are committed to creating the best products we can for our customers by working with our trusted suppliers, some of which we have worked with for over 10 years, and ensuring where possible we are developing collections made from responsible and quality fibres.

LEATHER WORKING GROUP

AllSaints is a member of the Leather Working Group (LWG), which has strict auditing standards to assess the performance of leather manufacturing facilities (or "tanneries") against environmental, social and governance metrics. This helps to ensure the chemicals used within the tanning process are managed efficiently.

The cattle and meat industry is one of the largest contributors to deforestation globally, therefore we’re working with our suppliers to become more traceable and transparent in the sourcing of our leather. This is a significant problem faced by the leather industry as a whole but we're committed to finding solutions with our suppliers.

RESPONSIBLE COTTON

Cotton accounts for over 50% of the fibres we use as a business each year, so it is an incredibly important fibre for us. However, we also know that cotton can have negative impacts on the environment and the farmers that grow it. This impact comes primarily in the shape of water consumption, as cotton uses a huge amount of water in its cultivation and dyeing processes, not to mention the large amounts of synthetic chemicals and pesticides it requires to grow.

We are committed to using as much organic cotton within our collections as possible, which when compared with conventionally-grown cotton, uses better growing practices such as no artificial pesticides, improved water irrigation techniques and encourages beneficial biodiversity.

For our organic cotton products, they are certified to either the Global Organic Textile Standard (GOTS) or Organic Cotton Standard (OCS). For our recycled cotton products, they are certified to either the Global Recycling Standards (GRS) or other known recycling standards.

ORGANIC FIBRES

ORGANIC CONTENT STANDARD

We are certified to the Organic Content Standard (OCS). Products

certified to the OCS standard contain organically grown material

that has been independently verified at each stage of the supply

chain, from source to final product.

Find out more

GLOBAL ORGANIC TEXTILE STANDARD

We are certified to the Global Organic Textile Standard (GOTS) from 2021. The GOTS standard requires any organic product certified to this standard to contain a minimum content of organic fibres (70%). In addition there are strict guidelines on natural and synthetic chemical inputs while having to meet high social parameters to protect workers throughout the supply chain. The aim of this standard is to promote environmentally and socially responsible manufacturing that is traceable from farm to final product. Find out more

ANIMAL FIBRES

RESPONSIBLE WOOL STANDARD

We are certified to the Responsible Wool Standard. The RWS standard verifies wool fibre animal welfare and land management requirements and tracks it from farm to final product. Find out more

RESPONSIBLE MOHAIR STANDARD

We are certified to the Responsible Mohair Standard. Products certified to the RMS Standard contain mohair fibre from farms (independently) certified to animal welfare and land management requirements. Find out more

NATURAL & CELLULOSIC FIBRES

TENCEL™ LYOCELL

TENCEL™ Lyocell fibres are derived from controlled or certified wood sources and are produced in a closed loop process which recovers 99.8% of the solvent - resulting in close-to-zero wastage. TENCEL™ fibres are naturally soft and smooth to the touch. TENCEL™ is a trademark of Lenzing AG. Find out more

TENCEL™ MODAL

TENCEL™ Modal are derived from controlled or certified wood sources. They are made with at least 50% less carbon emissions and water consumption compared to generic modal^. TENCEL™ fibres are naturally soft and smooth to the touch. TENCEL™ is a trademark of Lenzing AG. ^Results based on LCA standards (ISO-14040/44) and available via Higg MSI (Version 3.7) Find out more

LENZING™ ECOVERO™

LENZING™ ECOVERO™ branded viscose fibres are derived from controlled or certified wood sources. They are made with at least 50% less carbon emissions and water consumption compared to generic viscose^. LENZING™ and ECOVERO™ are trademarks of Lenzing AG. ^Results based on LCA standards (ISO-14040/44) and available via Higg MSI (Version 3.7) Find out more

HEMP

Hemp fabric has some great natural advantages, such as keeping you warm in winter, cool in summer and even protecting you from UV rays. It also requires far less water when compared to cotton, making it a great alternative.

COROZO

Our corozo buttons are made using natural materials from nuts harvested from the Tagua palm. They are produced with a distinctive grain finish, a nice non-plastic alternative.

RECYCLED & SYNTHETIC MATERIALS

SYNTHETIC FIBRES

There are many advantages of using synthetic fibres within our collection, they dry quickly, can be made to be waterproof, stain resistant, wrinkle free and long lasting. However, coal, oil or natural gases are all used in the production process, therefore we are committed to move away from virgin synthetic materials and instead incorporate more recycled fibres wherever possible.

RECYCLED FIBRES

Recycled materials can come from a variety of sources, from old

dead stock material, production process waste, recycled plastic

bottles, and fishing net waste to mention a few.

In an effort to reduce our virgin materials, we are certified to

the Global Recycling Standard (GRS). Products certified to the

Global Recycled Standard (GRS) contain recycled material that

has been (independently) verified at each stage of the supply

chain, from the source to the final product. In addition,

factories and everyone involved, from the source to final

supplier, have met social, environmental, and chemical

requirements.

Find out more

ECONYL® Regenerated Nylon

ECONYL® yarn is a 100% regenerated nylon fibre made from nylon waste, such as fishing nets, fabric scraps, carpet flooring and industrial plastic rescued from all over the world - which would otherwise be polluting the Earth. Find out more

Repreve®

REPREVE® is a branded synthetic performance fibre that is manufactured from the recycling of used plastic bottles and post-industrial waste sources. By recycling these bottles into a fibre, this helps reduce plastic waste within our environment. Find out more

WHO WE'RE WORKING WITH

LEATHER WORKING GROUP

We are a member of the Leather Working Group (LWG), a not-for-profit organisation that provides the world's leading environmental certification for the leather manufacturing industry. Find out more

CANOPY

Each year it is estimated over 150 million trees are logged for the textile industry alone. Since 2022, we’ve been working with non-profit organisation Canopy, with a mission to protect the world's forests, species and climate, as well as helping Indigenous communities. Their Pack4Good and CanopyStyle initiatives help brands like AllSaints to ensure our paper-based packaging and man-made cellulosic fibres are not sourced from ancient and endangered forests by 2025. Find out more

TEXTILE EXCHANGE

Textile Exchange is a non-profit organisation working towards making sectors relating to fashion and textiles create products in a more responsible way to support our planet, ecosystems, and communities. Through their Climate+ strategy, they’ve set out to direct the global textile industry towards achieving a 45% reduction in greenhouse gas emissions within the fibre and raw materials production stage by 2030. In AllSaints effort to help reach this goal, we are certified to a number of their standards relating to organic, recycled, and responsible animal fibres. Find out more

IDFL

IDFL is our accredited auditing and certifying body that has certified us for many of our responsible materials such as GOTS (Global Organic Textiles Standard) or RWS (Responsible Wool Standard). To maintain our certifications, they audit us on a yearly basis to ensure we are compliant with traceability, social and environmental parameters set by these standards. Find out more

THE PROCESSES WE USE

Many processes within the textile industry use high volumes of chemicals and water to create beautifully dyed and finished products. But there are some great alternatives which do not have the same impact on our environment, and we are working hard with our suppliers to put more of these practices into our collections.

CHROME-FREE TANNING

Found across some of our leather products we do chrome-free tanning. This means that the dyestuff used to tan the leather does not contain Chrome.

VEGETABLE TANNING

For some of our jackets, the leather-making process is carried out using vegetable tanning. Dyes are made from natural compounds such as nuts, fruits, tree bark, and leaves.

DOPE DYED FIBRES

Conventional dyeing of synthetic fibres can use a lot of energy and water in the process and emit large volumes of CO2. Dope dyed synthetic fibres divert this water and energy as the dye is inserted into the fibre while being extruded. This also makes the fibre stay brighter for longer which prolongs longevity - something we all want with our clothes.

HOW TO CARE FOR YOUR PRODUCT

We know and fully believe that the most sustainable thing you can do is love and cherish the items you already have in your wardrobe. We want you to enjoy our products for years to come.

However it can be confusing to know exactly what to do with your favourite AllSaints jeans or knitwear piece. So we’ve tried to provide you with everything you need to know about keeping your AllSaints pieces in good condition. Learn more

Click here to read more detailed info on care labels.

HOW TO REPAIR YOUR LEATHER PRODUCT

AllSaints Repair Rewear – as part of our ‘WE ARE RESPONSIBLE’ sustainability strategy, we’re now offering repairs on your favourite AllSaints leather apparel pieces, such as our iconic leather jackets.

Free until August 2024, this new circular initiative is available in the following London stores: Regent Street, Covent Garden, Jack’s Place and White City – with plans to expand to the rest of the UK in the near future.

LEARN MORE